Direct-to-film (DTF) is famous among teh business owners of the textile industry because of its innovative printing technology. DTF printing provides durability, high quality, versatility, and bulk production options.

To transform your business, the DTF printers are essential in providing the latest features at a very low cost. So, choose the best DTF printers by comparing them with the other brands and purchasing them to witness a significant change in your textile industry.

After purchasing your printer, the most important thing is to set it up properly so it will be ready to boost the production process. Generally, the dtf printer manufacturer provides information on setting up your DTF printers. But this blog will give you detailed information about the setup process of the DTF printers so that you can have an idea of what the digital printers offer you and how they differ from the traditional printing process.

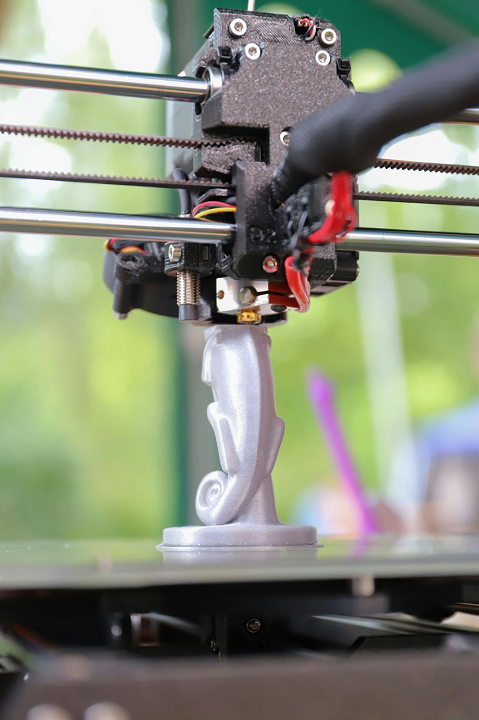

Unboxing of the DTF Printing Machine

As soon as you get access to the DTF printers, the first thing you have to do is carefully unbox the DTF printers and check all the components that are included in the package, such as transfer film, power cables, ink cartridges, or USB or network cables.

You must take into consideration that after you check all the printer components, you must sprinter A good ventilation is always good for the printers, therefore, it is always necessary to maintain the right temperature and stable humidity level.

Setting Yoour DTF Printer For Working

This step contains a long list of steps that are necessary to prepare your DTF printinter to work in the textile industry.

- In this first step, you have have to assemble the printer by positioning the printer properly, connecting the network or USB cables, and installing ink cartridges into their respective slots.

- The next step is to install the printer software, such as CD to your computer. You just have to read the instructions carefully and configure the printer settings, then you can also download the software or latest drivers smoothly.

- Transfer of the designs to the clothing is one of the most awaited part of printing. In this part you can first check for defects test on the prints, then you can apply the hot-melt powder for transferring the design. Or on the other hand, the peel off transfer films are ready for peeling off.

Conclusion

Are you preparing to obtain high-quality and reliable services through DTF printers? Then it requires to set up your DTF printers properly so that it operates uninterruptly and efficiently. Your custom apparel business can actually maintained by the DTF printers and for that reason, it requires mastering the setup process.

Read Also: Timewarp TaskUs: A Comprehensive Guide